The Secrets of Manual Winding Explained Simply

Why manual winding still captivates

In a world where everything is becoming automated, manual winding remains a profoundly human gesture. It’s the moment the mechanics wake up at your fingertips, when you take a minute to listen to the watch speak. The discreet clicking, the slight resistance building under the crown, then the reassurance of a seconds hand setting off again: winding isn’t merely a necessity, it’s a ritual. Collectors see it as a signature—this daily moment that anchors the watch in its owner’s life, from the Vallée de Joux to city wrists. It’s no coincidence that icons such as the Speedmaster “Professional” or a hand-wound Patek Calatrava continue to fascinate: they celebrate the discipline of a gesture and the beauty of mastered mechanics.

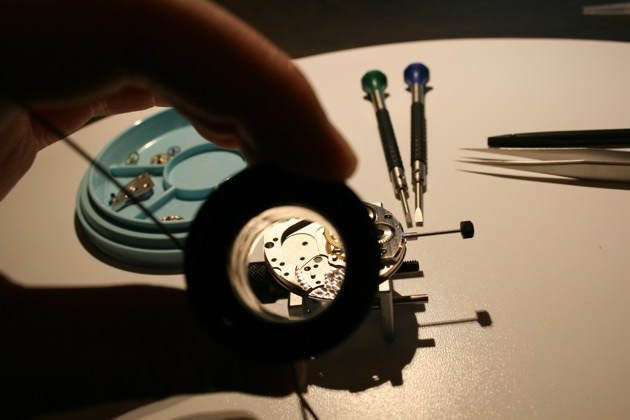

What happens under the crown: the mechanics decoded

Winding a watch means storing energy in a spring, then delivering it—metered—to the rest of the movement. Simple on the surface, exquisite in the details. Here, without unnecessary jargon, is the dance of the parts.

From the crown to the barrel

When you turn the crown, the stem drives a pinion that engages the winding wheel. This small kinematic chain transmits the motion to the ratchet wheel, fixed to the barrel arbor. With each click, the ratchet wheel turns the barrel, which coils the mainspring. The click, that tiny spring-loaded lever, prevents the ratchet from turning back: hence that muted sound, so addictive to mechanical-watch enthusiasts.

The mainspring and the art of metering

At the heart of it, the barrel spring stores energy. In a manual calibre, it is hooked to the arbor: you reach a firm stop when the spring is fully wound. In an automatic movement, a slipping bridle prevents over-tension and allows controlled slipping. What follows is a ballet: energy flows from the barrel to the gear train, then to the escapement, which chops it into regular impulses to make the balance oscillate. Your “winding” is thus converted into measurable time, second after second.

The right technique: how many turns, when, and how

People often talk about a “number of turns”. In reality, your watch answers you: it tightens, it speaks through touch. A few simple rules help you adopt the right gesture.

- Take the watch off your wrist. You’ll avoid putting strain on the stem and crown.

- Wind it every day, preferably in the morning. Timekeeping is more stable with the mainspring in its ideal torque range.

- Turn the crown in the winding direction (generally clockwise) with smooth motions. Depending on the calibre, 20 to 40 turns are enough.

- Stop as soon as the resistance becomes clearly firm. That’s the stop: forcing achieves nothing and can damage the mechanism.

- If your watch has a screw-down crown, unscrew it gently, wind, then screw it back down without over-tightening.

A power-reserve indicator, when present, makes everything easier: wind to full reserve, then let it run. Without an indicator, trust the feel. After a few days, muscle memory will do the rest.

Myths, mistakes, and truths

- “I can overwind it and break the watch.” On a calibre in good condition, you feel the stop. Stopping there is risk-free. Breakage happens when you force beyond it—rarely, and mainly on watches that are dry or poorly maintained.

- “You have to wind it in one go.” A full daily wind is best, but splitting it into two moments doesn’t harm the mechanism.

- “Automatics don’t need winding.” If you don’t wear them enough, an initial manual wind wakes up the oils and gets the watch running, especially after a long rest.

- “Winding immediately improves accuracy.” Mainspring torque does have an influence, yes, but accuracy is first and foremost a matter of regulation, lubrication condition, and position.

- “You have to wind until the final ‘click’.” There is no mystical final click: there is a clear resistance to respect. Your hand is the best indicator.

Protecting your movement: servicing, water resistance, and vintage pieces

A beautiful gesture deserves sensible precautions. Watchmaking isn’t temperamental; it’s logical.

- Servicing and lubrication: roughly every 5 to 7 years, depending on use. A dry mainspring or a worn click makes winding feel rough—your cue for a visit to the watchmaker.

- Water resistance: avoid winding in a humid environment. If the crown isn’t screw-down, it’s an entry point for condensation. After the pool, wait until the watch is completely dry before handling it.

- Vintage: on an older piece, wind slowly. Aged oils and fragile teeth call for gentleness. Have the gaskets and the spring’s condition checked: some period barrels can crack.

- Crown and stem: if you feel abnormal play or irregular notching, stop and have it checked. Better to prevent than to tear out a stem.

- Storage: if you leave a manual-wind watch at rest, wind it partially once a month to distribute the oils. Store it away from magnetic fields and shocks.

A word on power reserve: it often varies from 36 to 72 hours, sometimes far more. A morning routine is then enough to stay within the stable torque zone, which benefits consistency. It’s the wisdom of master watchmakers: fewer jolts, more constancy.

A cultural ritual: from the workshop to the wrist

It’s said that an old hand in the Vallée de Joux would wind each watch he repaired every morning, murmuring “See you tomorrow,” as one greets a travelling companion. That phrase says it all. Manual winding is a pact between you and the mechanics—a dialogue that ties the object to your rhythm. You find in it the spirit of Breguet, the rigour of A. Lange & Söhne, the restraint of a Nomos Tangente: an aesthetic of the right gesture, essential to setting an automatic watch.

On the Moon, the Speedmaster was operated by gloved hands; at a Parisian desk, a manual Tank is wound in the morning’s silence. Same mechanics, same emotion. In a world of screens, that daily quarter-minute relearns patience and precision. Winding is to watchmaking what tuning is to music: an introduction, a mark of respect, a promise.

Ultimately, understanding winding means learning to listen to your watch more closely. To recognise the texture of a well-oiled click, the firmness of a spring at full wind, the smoothness of a well-fitted ratchet. Simple words, precise gestures, and a reward: a mechanism that accompanies you, set to the tempo of your life. That is watchmaking’s best-kept secret: beauty isn’t only on the dial, but in the ritual that sets it in motion.