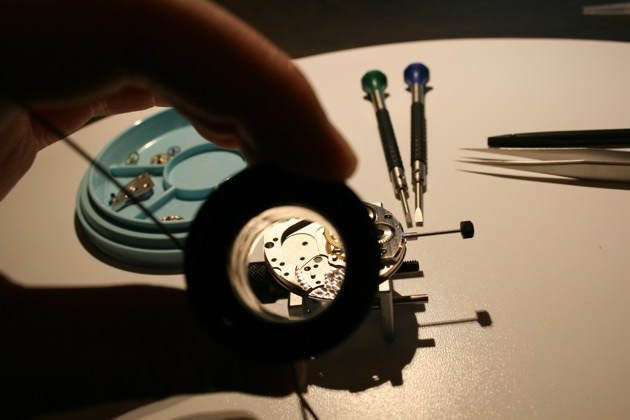

Watchmaking Materials

Steel, aluminium, carbon, platinum, titanium… The materials used in watchmaking are becoming increasingly diverse. Let’s take a look at the main materials in horology to better understand what our cases, bracelets and movements are made of.

Stainless steel

This is an alloy of iron, chromium and carbon.

It is generally found in its 316L variant in our watch cases, but it can be used for all parts.

The +: stainless

The -: its weight (7.9 g/cm3)

Aluminium

It allows for many alloys but is relatively uncommon in movements.

The +: very light (2.7 g/cm3)

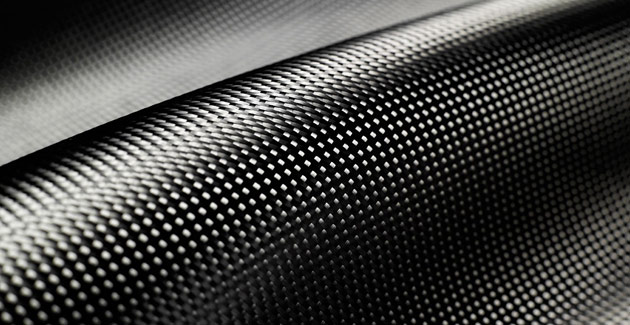

Carbon

It comes in several forms and can be part of alloys in steels, in surface coatings, as braided fibres, etc.

The +: its weight (1.8 g/cm3) and its resistance to compression.

The -: it breaks.

Invar

Its alloys make it possible to manufacture balance springs. Also known as FeNi36.

Brass

An alloy of copper and zinc produces brass, a very useful material for movement components.

The +: price, easy machining

The -: soft and prone to oxidation

Gold

Used mainly for cases and rotors.

- Yellow gold: 75% gold + 12.5% silver + 12.5% copper

- Rose gold: 75% gold + 6% silver + 19% copper

- Red gold: 75% gold + 25% copper

- White gold: 75% gold + palladium and silver

The +: stainless, beautiful

The -: expensive, heavy, and a high coefficient of thermal expansion

Platinum

Platinum is mainly used for cases in its purest form.

Its advantages and drawbacks are similar to those of gold.

Silicon

It can be used for escapements or for external components (as an alloy).

The +: light, can be engraved, economical, stainless and self-lubricating.

The -: brittle.

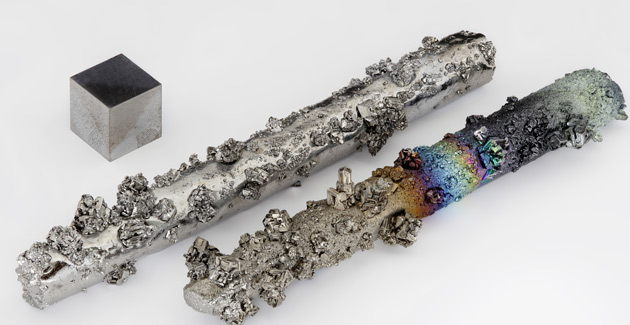

Titanium

Used mainly in cases.

The +: light, stainless, robust.

The -: difficult to work with and has high thermal inertia.

Tungsten

The base of tungsten carbide used as a ceramic.

The +: economical, stainless and hard.

The -: difficult to work with