Sapphire as a Watch Case Material: Advantages and Manufacturing Techniques

In the world of haute horlogerie—where precision meets luxury—few components are as coveted as sapphire watch cases. Celebrated for their exceptional clarity, durability and elegance, sapphire cases are produced through a meticulous manufacturing process that combines advanced technology with skilled craftsmanship. Let’s explore the intricate journey behind these exquisite watch cases, distilled into five key stages.

Manufacturing synthetic sapphire

A. Selecting the seed crystal

The Verneuil process begins with the selection of a small sapphire crystal known as a seed crystal. This crystal serves as the foundation on which the synthetic sapphire boule will grow.

B. Preparing the powder

Aluminium oxide powder—also known as alumina or corundum—is carefully prepared for the growth process. The powder is often sourced at very high purity to ensure the quality and consistency of the resulting sapphire crystal, used in particular for sapphire watch cases.

C. Flame fusion

In the Verneuil process, aluminium oxide powder is fed into a high-temperature flame generated by specialised equipment, such as an oxyhydrogen torch. The intense heat melts the powder, forming droplets that fall onto the seed crystal.

D. Crystal growth

As the molten alumina droplets come into contact with the seed crystal, they solidify and gradually build up layer by layer, forming a cylindrical boule. The growth rate and conditions are carefully controlled to achieve the desired crystal structure and quality.

E. Cooling and solidification

Once the desired size and shape have been reached, the sapphire boule is slowly cooled to room temperature, allowing the crystal structure to solidify. This gradual cooling helps minimise internal stresses and defects within the crystal, ensuring optimal quality and uniformity.

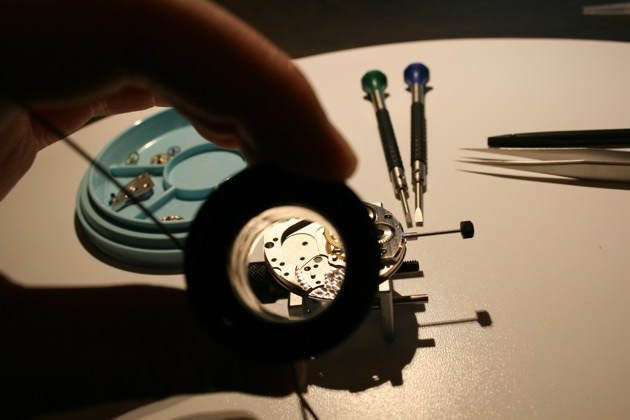

Machining and polishing

With the rough blanks in hand, the next step is to grind and polish them to achieve the required dimensions, clarity and surface finish. Specialised machines fitted with diamond grinding wheels and polishing compounds are used to meticulously refine the sapphire blanks. This process removes imperfections such as surface irregularities and scratches, while imparting a mirror finish to the crystalline surface. It is a delicate dance of precision and finesse, ensuring that every sapphire watch case meets the highest standards of quality and aesthetics.

For complex designs or cases requiring tight tolerances, computer numerical control (CNC) machining comes into play. Using computer-guided cutting tools, CNC machines sculpt sapphire blanks with unmatched accuracy and repeatability. This advanced machining process makes it possible to create complex geometries—such as intricate bezels, lugs and crown guards—with meticulous attention to detail. From traditional round cases to avant-garde shapes, CNC machining opens up a world of creative possibilities in sapphire watch-case design.

Quality control

Throughout the manufacturing process, rigorous quality-control measures are applied to uphold the highest standards of craftsmanship and durability. Visual inspections, dimensional measurements and structural integrity tests are carried out at various stages to verify compliance with exacting specifications. Once deemed flawless, sapphire watch cases undergo final touches, which may include surface treatments such as sandblasting, polishing or satin finishing to achieve specific textures or aesthetics. With every detail meticulously examined and perfected, each sapphire watch case emerges as a masterpiece of watchmaking art, ready to house an exceptional timepiece.

In conclusion, the journey of manufacturing sapphire watch cases symbolises the marriage of technology and artistry, where precision engineering meets timeless elegance. From the creation of synthetic sapphire crystals to the painstaking processes of machining and finishing, each stage bears witness to the dedication and expertise of master artisans. As these exquisite cases find their place in the world of haute horlogerie, they stand as enduring symbols of luxury, durability and uncompromising quality.