Introduction to Disassembling & Reassembling a Mechanical Movement

It was a wonderful experience that I was able to enjoy recently, taking part in an introductory workshop organised by the Fondation de la Haute Horlogerie in Geneva.

These workshops invite participants to step into the shoes of a watchmaker and disassemble and reassemble a mechanical movement in the comfort of the Palais de l’Athénée, guided by two attentive watchmakers and using high-quality tools (Bergeon, for the curious).

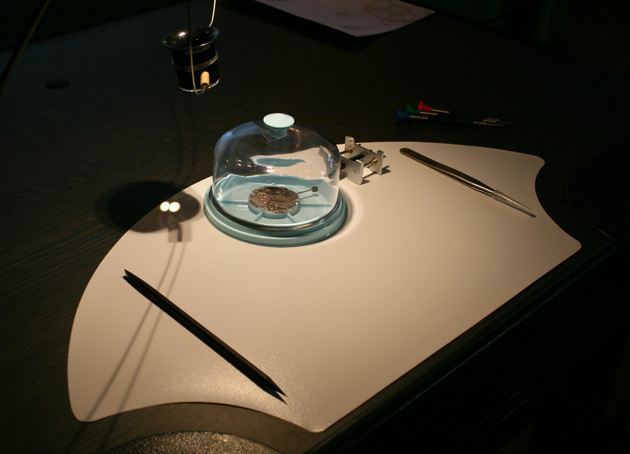

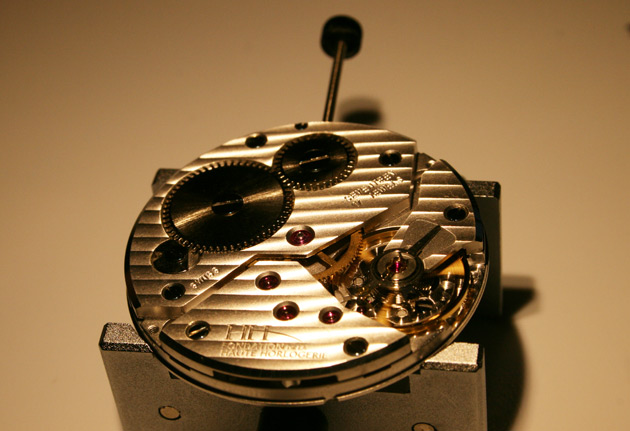

After a brief introduction to the basic principles of watchmaking, we get down to business with a look at our tools and the movement.

On the bench: three screwdrivers, tweezers, a plastic stick, a loupe, a covered tray with compartments, a movement holder (watchmaker’s vice) and… the movement.

The movement is an ETA 6497-1, a true “tractor”: reliable and virtually indestructible, and for decades it has found its way into countless watches. It displays the hours, minutes and a small seconds sub-dial at 9 o’clock.

Power reserve is 46 hours, and it beats at 18,000 vph.

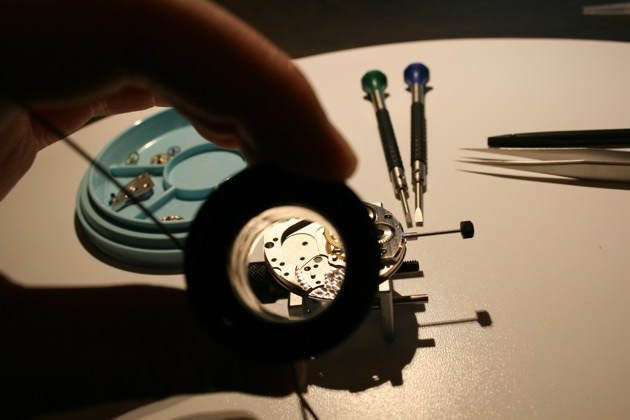

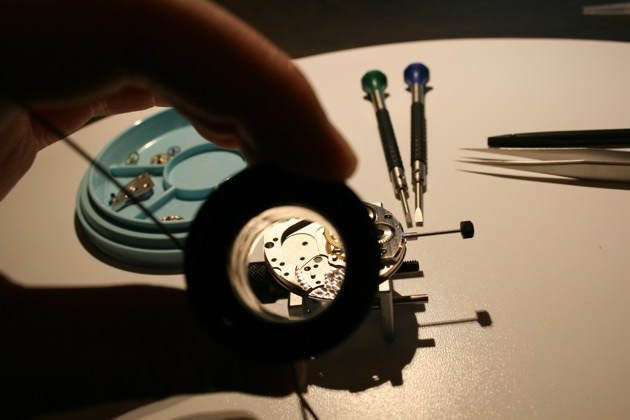

With the watchmakers’ invaluable guidance, disassembly begins, loupe adjusted over the eye to handle as deftly as possible the 78 parts that make up the movement.

First and foremost, you have to learn the right techniques: how to handle the movement, how to let down the mainspring before taking anything apart, how to lift the bridges using the slots on the sides, how to pick up wheels by their centre, and how to tighten screws without forcing or slipping, so as not to damage the components.

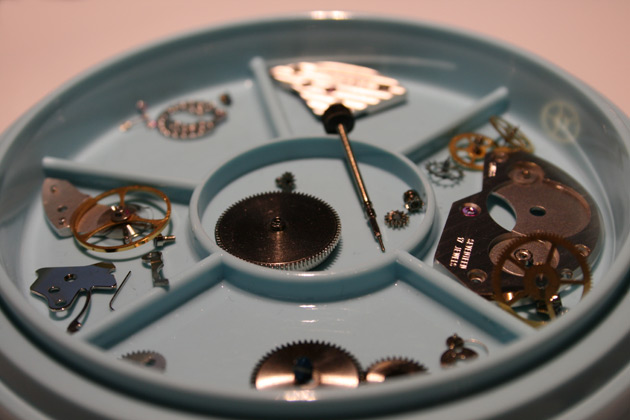

The more delicate steps are demonstrated by the instructors. It’s also an opportunity to discover the impressive length of an uncoiled mainspring. This long “string”, shaped like a treble clef, has to go back into the barrel shown just to the left in the image.

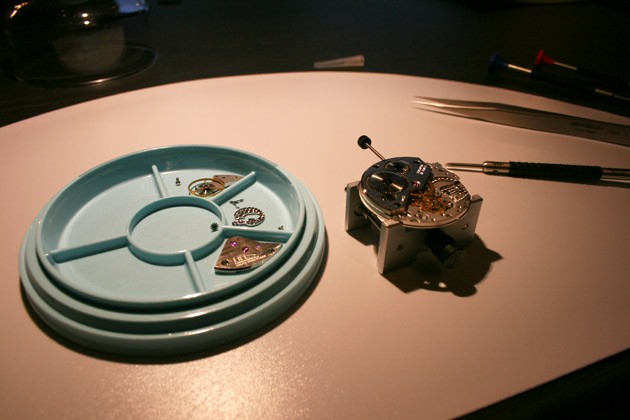

The mainplate is stripped bare as the compartments fill up with the parts we’ve removed.

Once disassembly is complete, and after a break that’s perfect for conversations among enthusiasts, it’s time to reassemble. The only downside: as part of this workshop, we won’t be oiling the components.

The stick is far from useless for holding the yoke spring, which has a strong tendency to jump out of the movement at the slightest assembly mistake.

With the balance and hairspring (which regulates the energy delivered by the mainspring and distributed by the escapement) and its bridge assembled, it’s time to pick up the bûchette (or stick) to check that the hour spent reassembling the movement is going to pay off.

A gentle nudge to the balance and hairspring and… the movement comes back to life!

Satisfaction is at its peak when faced with the beauty of this mechanism, brought to life by fabulous watchmaking know-how and, to a far lesser extent (on the order of a nanometre), by us!

If you would like to take part in a workshop, here is some practical information:

- Time: 6pm–9pm

- Dates: the first Wednesday of each month.

- Registration fee: CHF 350.-/ person.

- Venue: 2 Rue de l’Athénée – 1205 Geneva

- Registration: info@hautehorlogerie.org